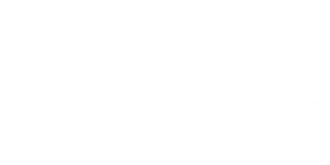

6 steps to NFPA compliance

A structured approach to help organizations meet the standards set by the National Fire Protection Association (NFPA). These steps are commonly cited in fire safety and compliance planning, especially in industrial or commercial environments. Here are the six steps:

1.

Qualified Person (P. 70E-13)

Electrical Safety Training (Employee)

One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify the hazards and reduce the associated risk.

Training should be documented and refreshed every 3 years to stay in compliance with codes and standards.

2.

Article 205.4 General Maintenance Requirements. (P. 70E-43)

Perform Maintenance on Electrical Equipment

Electrical equipment shall be maintained in accordance with manufacturers’ instructions or industry consensus standards to reduce the risk associated with failure. The equipment owner or the owner’s designated representative shall be responsible for maintenance of the electrical equipment and documentation.

3.

Article 110.3 Electrical Safety Program (A) General. (P. 70E-16)

Electrical Safety Program

The employer shall implement and document an overall electrical safety program that directs activity appropriate to the risk associated with electrical hazards. This must be updated every three years.

4.

Article 130.1 Working While Exposed to Electrical Hazards. (P.70E-24)

Identify Electric Shock and Arc Flash Hazards for Employees and Label Equipment Appropriately.

Safety-related work practices shall be used to safeguard employees from injury while they are exposed to electrical hazards from electrical conductors or circuit parts that are or can become energized.

1. Only qualified persons shall be permitted to work on electrical conductors or circuit parts that have not been put into an electrically safe work condition.

2. An energized electrical work permit shall be completed as required by 130.2.

3. An electrical shock risk assessment shall be performed as required by 130.4.

4. An arc flash risk assessment shall be performed as required by 130.5.

5.

Article 130.7 Personal and Other Protective Equipment. (P. 70E-29) (A) General.

Provide the Appropriate (PPE) Personal Protective Equipment.

Employees exposed to electrical hazards when the risk associated with that hazard is not adequately reduced by the applicable electrical installation requirements shall be provided with, and shall use, protective equipment that is designed and constructed for the specific part of the body to be protected and for the work to be performed.

6.

Article 120.6 Process for Establishing and Verifying an Electrically Safe Work Condition. (P. 70E-23)

Generate and Keep Facility Drawings Updated for Employees and Contractors

(1)Determine all possible sources of electrical supply to the specific equipment. Check applicable up-to-date drawings, diagrams, and identification tags.

Article 205.3 Single-Line Diagram. (P. 70E-43) A single-line diagram, where provided for the electrical system, shall be maintained in a legible condition and shall be kept current.

Associations and Credentials